SmartRamp System

One common error in shipping processes is sending incorrect pallets to the final customer. Beyond the costs of retrieving wrongly delivered pallets and reshipping the correct ones, additional losses occur due to customer dissatisfaction, potential contractual penalties, and negative impacts on the company's image and reputation. Our loading ramp control system eliminates transport errors when dispatching pallets with finished products. The solution reads the pallet label number as it passes through the loading ramp and immediately verifies the loading accuracy against the shipping order.

Depending on customer requirements, we select technology based on scanners, scanners with oscillating mirrors, or vision cameras, which allows us to tailor the effectiveness of operations and optimize solution costs.

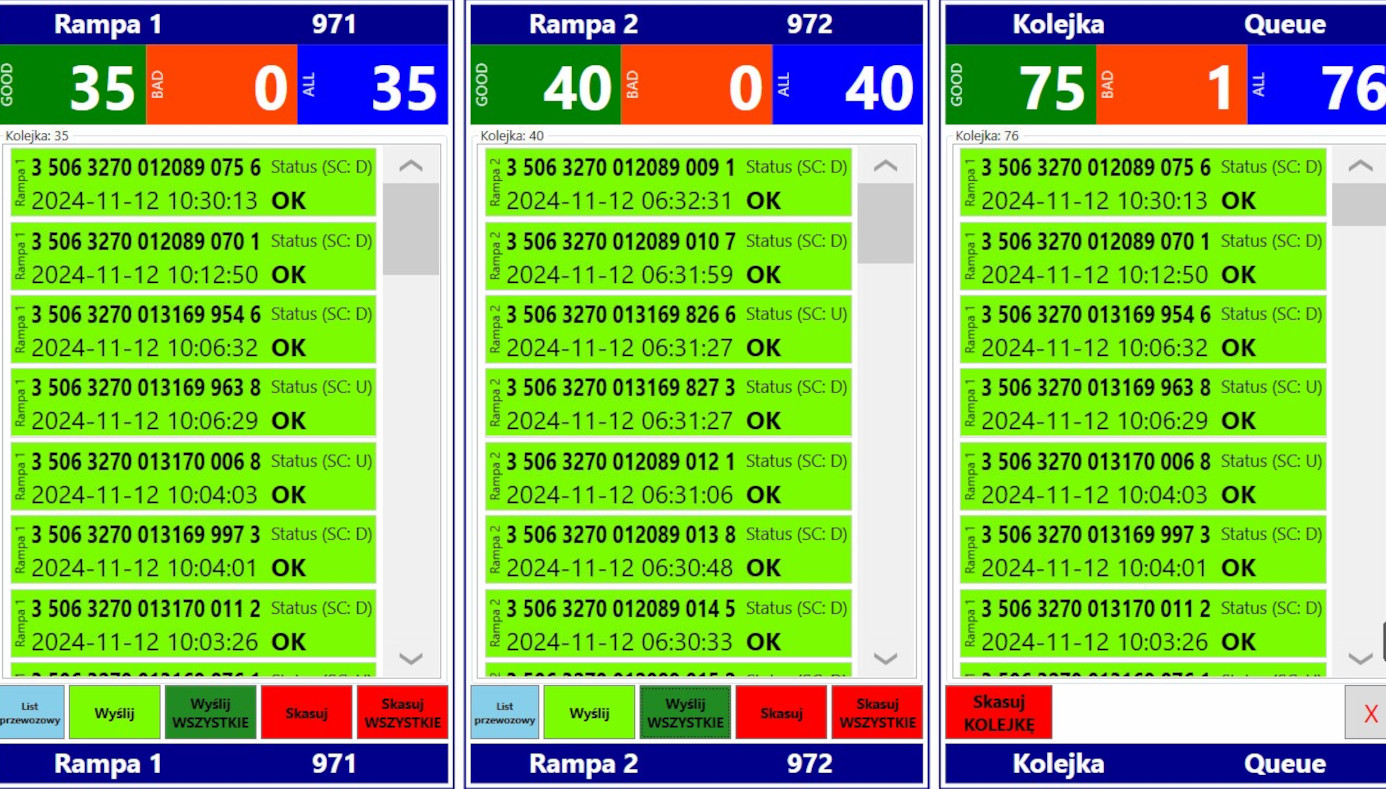

The forklift operator drives through the loading ramp at normal speed. The system scans the pallet label, providing feedback on the reading's accuracy and compliance with the transport order via a signal column. Detailed data about the scanned pallet is then displayed at the system status visualization station.

The system logs loaded pallets, recording label numbers and loading times for each pallet. All this information is displayed clearly for the forklift operator. Additionally, the solution enables offline operation in the event of a primary system (SAP/WMS) failure. In offline mode, the system stores scanned pallet labels and allows a delivery note to be generated according to a preset template upon loading completion. When the primary system regains functionality, all completed transport operations are automatically synchronized with the relevant systems.

- Error-Free Product Shipping – automatic pallet label scanning during passage through the loading ramp

- Improved Efficiency – operators save time by avoiding manual label scanning

- Enhanced Ramp Productivity – single loading operations take less time due to reduced manual tasks

- Reduced Operational Costs – no logistical errors, faster loading, and improved work efficiency

- Increased Workplace Safety – operators remain in the forklift without dismounting to scan labels

- Reporting – the system stores data on each load, including start and end times for loading operations

- Energy Savings – efficient loading management reduces equipment, machinery, and vehicle runtime

- Eco-Friendliness – lower energy/fuel usage and reduced carbon footprint from fewer unnecessary forklift runs and maneuvers

- Low Total Cost of Ownership (TCO) – modern web-based interface, no client-end application installation required, simple system updates

- Improved Customer Satisfaction – ensuring deliveries meet specifications and schedules

- Pallet Verification at Dispatch – label scanning occurs during the actual entry onto the transport trailer or when passing through the loading ramp

- Clear Visualization – real-time display of pallet counts and quantities at system visualization stations

- Integration with Parent Systems – adaptable for integration with WMS/ERP systems or standalone operation

- Autonomous Operation Modes:

- Delivery Note Generation – the system logs pallet numbers loaded onto the transport trailer and generates a delivery note

- Verification of Expected Pallet Numbers – checks if loaded pallet numbers match a predefined delivery list

- Elimination of Warehouse Errors – reduces mistakes caused by habits like pre-staging pallets for dispatch and separating label scanning from loading. Common issues include pallet mix-ups, unscanned pallets, ramp errors, and communication mishaps during operator shift changes.

- High System Scalability – supports multiple loading ramps simultaneously

- Offline Functionality – generates delivery notes and dispatches goods offline during ERP/WMS downtime; data synchronizes once systems are back online

- High Configurability:

- Define any number of system visualization devices

- Set up management endpoints for individual loading ramps

- Use mobile scanners for emergencies (e.g., labels in non-standard locations or damaged labels)

- Allow manual label input for damaged labels

- Connect multiple handheld devices/scanners as per client needs

- No User-Side Installation Required – web-based system accessible via an internet browser

- Mobile Scanning Station Option – for situations requiring pallet verification in warehouse-to-warehouse transport

Case Study

At the client facility, loading finished goods onto ramps was carried out informally. Each operator followed personal habits, and the process lacked formal documentation.

Operators staged pallets near ramps. Once all pallets were collected, they parked the forklift and scanned pallet labels to create a delivery note. These pallets awaited truck arrival. A similar process occurred at other ramps.

Due to limited buffer space, pallets for different clients were stored closely, increasing the risk of mix-ups. Delayed transport arrivals occasionally caused pallets to remain in the buffer zone, with the next operator shift handling loading. This led to errors, such as dispatching incorrect pallets. Consequently, costly operations ensued to retrieve incorrect pallets and resend the correct ones. Given the client’s European-wide distribution, such errors resulted in significant logistical costs.

Attempts to formalize the loading process did not eliminate errors. To address these challenges, the client ordered a system to control pallet verification during entry onto the transport trailer. Our solution, SmartRamp, instantly detects and reports incorrectly loaded pallets, preventing delivery note finalization until the incorrect pallet is removed.

Benefits of SmartRamp Implementation

- 100% elimination of pallet shipping errors – no costs for returns and reshipping

- Accelerated loading operations – no manual label scanning by operators

- Cost reductions – fewer operators and forklifts achieve the same output

- Systematization of shipping preparation processes

- Offline operation capability – ensures continued shipping during ERP system downtime

- Improved efficiency, error reduction, and cost savings in logistics processes

We invite you to explore SmartRamp – a solution ensuring greater efficiency, reduced errors, and savings in your logistics processes.