CallOff System

The CallOff System leverages the Kanban methodology to ensure the precise delivery of components to the right machines, at the right time, and in the required quantities. This minimizes errors and streamlines logistics, enhancing production efficiency while lowering operational costs.

By integrating advanced monitoring and control features, CallOff eliminates quality issues during the supply of components from raw material warehouses to production machines.

The system integrates with sensors that monitor the usage of raw materials and supplies, enabling automatic reordering of missing components in the warehouse. As a result, production line operators no longer need to constantly monitor inventory levels, allowing them to focus on tasks essential for maintaining the continuity of production line operations.

The implementation of the CallOff system delivers significant business benefits, including increased operational efficiency, inventory optimization, reduced operational costs, improved communication and collaboration within the facility, and enhanced control over production processes.

A well-functioning system also lays the groundwork for the full automation of component deliveries in the future, such as through the use of autonomous AGV carts.

Additionally, the CallOff system provides complete functionality for a materials and supplies ledger maintained in an electronic format. The ledger is updated in real-time with precise tracking of each component delivered in every shipment, detailing allocation by production lines, tooling setups, components, lead times, and other specifics.

- Elimination of errors in component deliveries to production lines– every component is verified before delivery to the production line.

- Improved operator efficiency– automated ordering of production-required components relieves operators from constant monitoring of inventory and production line requirements.

- Error-free machine retooling, including quick retooling (changing only part of the components) – components that could be mistakenly used are not stored near production machines.

- Optimization of the component warehouse operations– predicting when components will be needed for machines and production lines reduces the workload for warehouse staff.

- Streamlined communication between departments– electronic information flow regarding production plans, machine retooling, and component requirements.

- Production efficiency reporting– the system provides real-time data for analyzing and tracking process performance.

- Optimized production management– bottlenecks are identified based on comprehensive information about material flows and production statuses.

- Enhanced workplace safety– a more organized production floor environment.

- Efficient use of production floor space– no stored components around machines allows for more machines or production lines to be accommodated in the same area.

- Reduced risk of component damage during delivery– components are delivered just-in-time, eliminating the need for on-floor storage.

- Reduced paper documentation– electronic workflows ensure production plans are delivered directly to specific lines.

- Low Total Cost of Ownership (TCO)– modern web-based interface, no need for application installation on client devices, and simple system updates.

CallOff

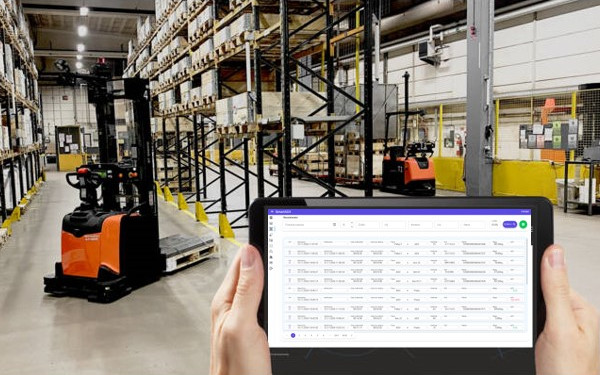

CallOff in Action: Key Capabilities

Any questions?

Want to know more?

- End-to-End Material Tracking: Monitors components from procurement to production, ensuring transparency at every stage.

- Component Returns Management: Prevents misallocation of unused components by ensuring proper return and tracking.

- Real-Time Data Visualization: User-friendly graphical interfaces provide an overview of system status across production and warehouse operations.

- Mobile Integration: Supports portable devices like RFID scanners and tablets for on-the-go operations and verification.

- Multi-Station Monitoring: Displays system status on production and warehouse floor monitors for quick access to information.

- Customizable Workflows: Adapts to unique production and logistics needs, offering high configurability.

- Web-Based Accessibility: Operates through a browser-based interface, eliminating the need for client-side installations and simplifying updates.