SmartAGV System

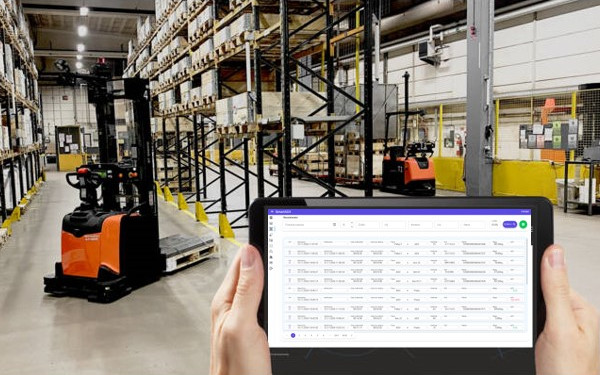

The SmartAGV System is a cutting-edge solution for managing and optimizing transport orders for fleets of autonomous guided vehicles (AGVs). By prioritizing tasks, merging missions, and accounting for specific plant conditions, SmartAGV enhances efficiency, reduces operational costs, and maximizes the potential of your AGV fleet.

With customizable settings, users maintain full control over task selection and execution order, adapting operations to unique facility requirements.

The template creation mechanism allows for quick switching between different AGV fleet work profiles. We collect data on completed missions for further analysis and optimization of operations. This enables the execution of a higher number of transport tasks with fewer carts, leading to a reduction in the costs of purchasing and maintaining the currently used AGV solution.

Statistics show that customers using our solution increase the efficiency of their autonomous fleet usage by up to 32%.

- Cost Efficiency: Optimizes AGV usage, reducing wear and operational expenses.

- Task Prioritization: Based on criteria like mission type, urgency, weight, location, and cargo.

- Templates allow dynamic adjustments to priority profiles.

- Unified Management: Manages both AGV and manual forklift operations through a shared system. Enables seamless task delegation between AGVs and operators, particularly during peak loads or system downtimes.

- Buffer Zone Handling: Facilitates material handoffs between vehicles for complex transport missions.

- Integration with ERP/WMS Systems: Streamlines communication with enterprise resource planning and warehouse management systems for efficient task allocation.

- Comprehensive Reporting: Identifies “bottlenecks” and inefficiencies in transport workflows.

- Multi-Vendor Compatibility: Integrates AGVs from various manufacturers into a unified management system.

- Web-Based Interface: Eliminates the need for local installations, ensuring ease of use and maintenance.

- User Roles and Permissions: Provides granular control over system functionalities.

- Cost Efficiency: Optimizes AGV usage, reducing wear and operational expenses.

- Higher Productivity: Increases the efficiency of individual AGVs, enabling more tasks with fewer vehicles.

- Improved Safety: Incorporates safety features, such as mission blocking based on external conditions (at selected stations/zones, locations)

- Enhanced Oversight: Tracks and evaluates manual forklift operations, ensuring task accuracy and time management.

- Vendor Independence: Allows the integration of AGVs from multiple suppliers, ensuring scalability.

- Low Total Cost of Ownership (TCO): Features a modern, user-friendly web interface and minimal setup requirements.

Case Study

A manufacturing facility faced challenges in monitoring manual forklift operators and optimizing transport efficiency. Internal attempts to assess operator workloads were ineffective, prompting the implementation of SmartAGV.

As part of the planned implementation of an autonomous forklift, we proposed the launch of the Smart AGV system, which was designed to manage all transport orders within the client's warehouse and production space. With the implementation of our system, management received detailed data and reports on the number of transport orders, their execution times, shift workloads, and other specific parameters.

Analysis of these reports enabled the reassignment of two employees during the shift to other tasks in the warehouse and production areas. Additionally, based on data from the Smart AGV system, areas and potential buffer zones were identified, allowing for the introduction of autonomous forklifts.

Based on estimated savings, the decision was made to purchase and implement the first AGV forklift. Routine and less urgent tasks were assigned to the AGV, while tasks requiring quick responses remained assigned to manual forklift operators.

After the successful implementation of the AGV forklift and optimization of task priorities and queues within the Smart AGV system, further data was collected regarding all transport orders in the plant. The analysis of the data gathered over the following months enabled the identification of additional opportunities to optimize transport processes in the facility.

Why Choose SmartAGV?

By implementing SmartAGV, facilities achieve immediate savings through automation, better resource allocation, and enhanced operational insight. It’s the perfect solution for businesses aiming to streamline logistics, boost productivity, and future-proof their transport systems.